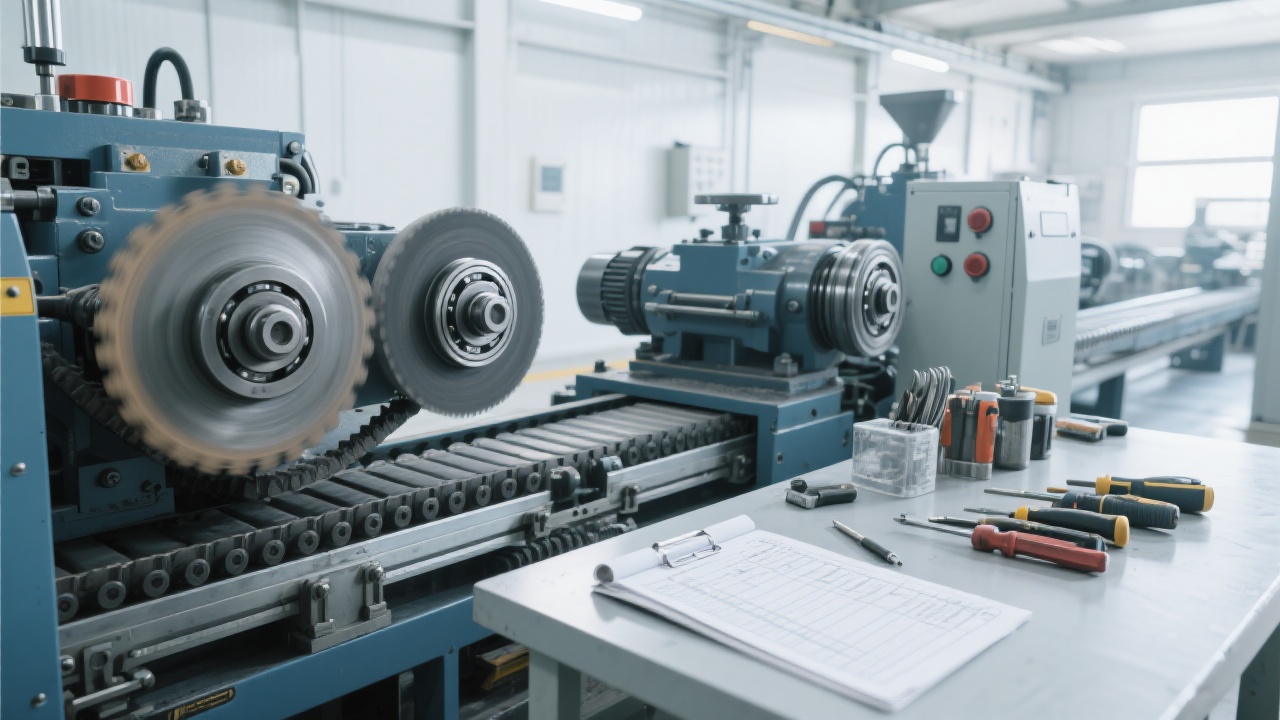

The machining of graphite components on CNC machines demands precise control of cutting parameters to address common challenges such as tool chipping and burr formation. This is especially critical in sectors like new energy battery manufacturing and mold fabrication, where machining quality directly impacts product performance and yield. Leveraging advanced features such as the wet flushing system integrated into graphite machining centers like the DC6060G delivers enhanced thermal control and efficient dust removal, safeguarding tool life and part integrity.

Selecting the appropriate tool material and geometry is foundational to mitigating chipping during graphite milling. Polycrystalline diamond (PCD) tools are preferred due to their exceptional hardness and wear resistance, which reduce edge degradation under harsh cutting conditions. However, parameter settings are equally pivotal. Typically, these parameters include spindle speed, feed rate, and depth of cut, which must be optimized to balance machining efficiency with tool longevity.

| Parameter | Recommended Range | Purpose |

|---|---|---|

| Spindle Speed (RPM) | 12,000 – 18,000 | Reduces tool wear and improves surface finish |

| Feed Rate (mm/min) | 800 – 1,200 | Balances material removal and cutting stability |

| Depth of Cut (mm) | 0.2 – 0.5 | Minimizes cutting forces and tool chipping |

The wet flushing system is a transformative technology integrated into the DC6060G graphite machining center, providing two main advantages: effective cooling and comprehensive removal of graphite dust. Unlike dry machining, which often leads to heat accumulation and tool edge degradation, the wet flushing system maintains a stable cutting temperature, drastically reducing thermal stresses.

Furthermore, graphite dust, if not efficiently cleared, can cause abrasive wear and affect machine components. The fully sealed design combined with the wet flushing mechanism creates a clean machining environment, protecting equipment and reducing maintenance downtime by up to 30%. This leads to higher uptime and consistent product quality in demanding industrial settings.

Persistent issues of tool chipping and burr formation often stem from improper parameter settings or overlooked process conditions. Engineers can adopt a systematic quick-check approach to identify root causes:

Incorporating these steps into a rapid self-diagnostic checklist enhances response times and mitigates scrap or rework costs.

Given the stringent quality requirements in new energy batteries and mold manufacturing, integrating these practices can elevate process reliability and part consistency. For instance, reducing burrs decreases the need for secondary finishing processes, improving production throughput by up to 15%. Moreover, tool longevity gains enabled by proper machining parameter selection and environmental control ensure better cost efficiency over the equipment lifecycle.