In 2024, the manufacturing industry has witnessed significant advancements in vacuum technology. One of the key trends is the development of full-sealed enclosure designs and high-efficiency dust collection devices. These technological innovations not only improve the overall performance of vacuum equipment but also address critical issues in the manufacturing process, such as dust control and equipment corrosion.

The full-sealed enclosure design provides a physical barrier that effectively prevents graphite dust from escaping into the environment. According to industry research, in traditional graphite processing environments without proper sealing, dust emissions can reach up to 20% of the total graphite material processed. This not only poses a health risk to workers but also causes corrosion to equipment, reducing its service life by up to 30%. In contrast, the full-sealed enclosure design can reduce dust emissions to less than 5%, significantly improving the working environment and equipment durability.

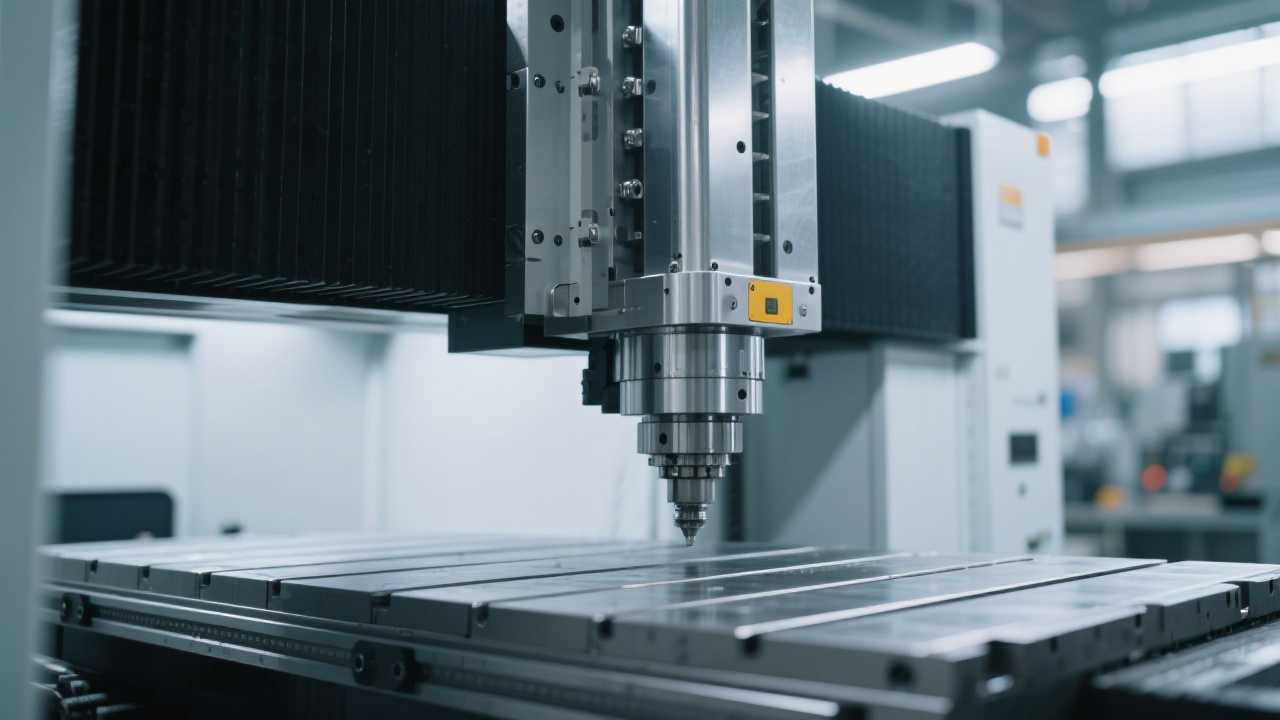

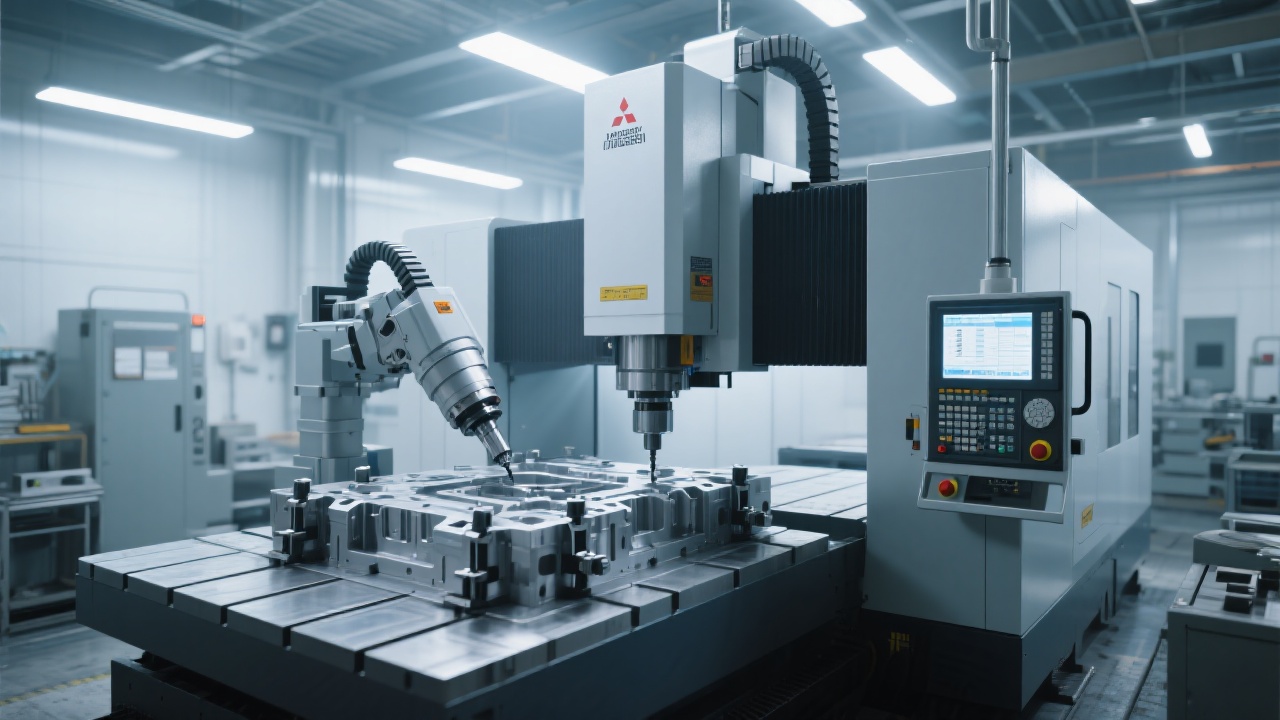

The dry vacuum graphite machining center DC6060G is a prime example of the application of these advanced vacuum technologies in graphite processing. Equipped with a full-sealed enclosure and a high-efficiency dust collection device, this machining center offers excellent dust prevention and corrosion resistance.

In a case study of a graphite manufacturing plant, the implementation of the DC6060G machining center led to a remarkable improvement in production efficiency. Before using the DC6060G, the plant had a high rate of equipment failure due to graphite dust corrosion, resulting in an average of 10 days of production downtime per year. After the installation of the DC6060G, the equipment failure rate decreased by 80%, and the annual production downtime was reduced to less than 2 days. This not only saved production costs but also increased the overall output of the plant by 15%.

Another significant development in the field of vacuum technology is the integration of intelligent manufacturing technology. Real-time monitoring and automatic fault diagnosis systems have become standard features in modern vacuum processing equipment, enabling manufacturers to achieve a more efficient and stable production environment.

The real-time monitoring system continuously collects data on various parameters of the vacuum equipment, such as temperature, pressure, and vibration. This data is then analyzed to detect potential issues before they cause significant problems. For example, by monitoring the temperature of the vacuum pump, the system can detect abnormal heat generation, which may indicate a problem with the pump's bearings or lubrication. Early detection allows for timely maintenance, preventing costly breakdowns and reducing production disruptions.

The automatic fault diagnosis system uses artificial intelligence algorithms to analyze the collected data and identify the root cause of any faults. In a large-scale manufacturing facility, the implementation of an intelligent vacuum processing system reduced the time required for fault diagnosis from an average of 24 hours to less than 2 hours. This significantly improved the responsiveness of the maintenance team and minimized the impact on production.

To provide a more comprehensive understanding of vacuum technology and its applications, this article uses a variety of content forms, including text, images, and videos. Additionally, technical whitepapers are available to provide in-depth technical information for professionals in the industry.

We also encourage user engagement through interactive elements such as Q&A sessions and online seminars. These activities allow users to ask questions, share their experiences, and receive professional advice. By actively participating in these interactions, users can gain a deeper understanding of vacuum technology and its practical applications in their specific industries.

Are you facing similar challenges in your graphite processing or manufacturing operations? Do you want to learn more about the latest vacuum technology solutions? Join our online discussion or contact us for more information. Click here to explore how our advanced vacuum technology can transform your production process!