Graphite is a vital material in various industrial applications due to its excellent physical and chemical properties. However, during the machining process, graphite generates a significant amount of fine dust. These dust particles can cause severe corrosion and contamination to machine parts and electronic components. According to industry research, approximately 40% of equipment failures in graphite processing plants are related to dust - induced damage. This not only leads to frequent equipment breakdowns but also reduces production efficiency and increases maintenance costs.

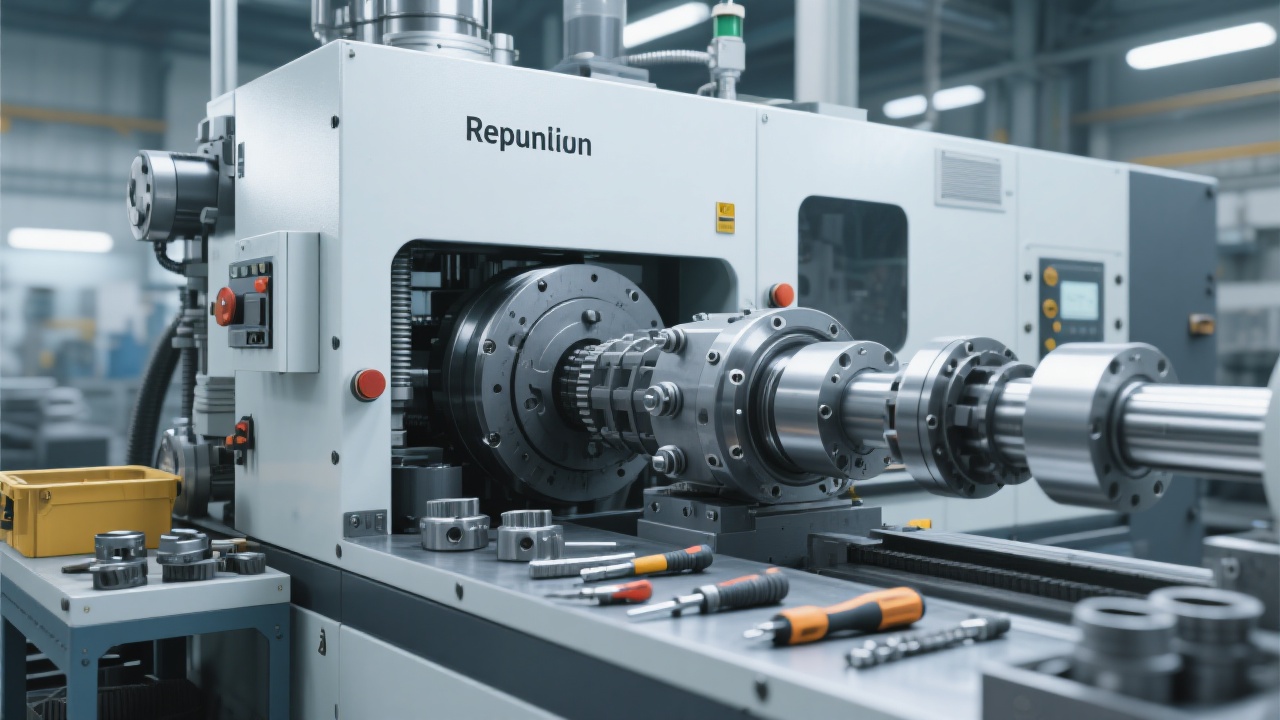

The DC6060G dry vacuum graphite machining center features a unique full - sealed enclosure design. This design effectively isolates the machining area from the external environment, preventing graphite dust from escaping. The enclosure is made of high - strength materials with excellent sealing performance. The sealing principle is based on a multi - layer sealing structure, which can block more than 95% of dust particles. This significantly reduces the risk of dust entering the internal components of the machine tool, ensuring the normal operation of the equipment.

In addition to the full - sealed enclosure, the DC6060G is equipped with a high - efficiency dust collection device. The working mechanism of this device is based on advanced vacuum suction technology. It can quickly and effectively collect graphite dust generated during the machining process. The dust collection efficiency can reach up to 98%. The collected dust is then stored in a special dust collection tank, which is convenient for subsequent disposal. This not only keeps the working environment clean but also reduces the impact of dust on the health of workers.

Regularly checking the sealing performance of the full - sealed enclosure is crucial. It is recommended to conduct a sealing inspection at least once a week. This can be done by using a pressure - testing device to check if there are any air leaks. If any leakage is found, the sealing strips should be replaced immediately to ensure the effectiveness of dust prevention.

The dust collection system needs to be cleaned and maintained regularly. The dust collection tank should be emptied at least once a month, and the filter elements should be replaced every three months. This ensures the normal operation of the dust collection device and maintains its high - efficiency dust collection performance.

Maintaining a clean working environment is also an important part of equipment maintenance. The floor and surrounding areas of the machining center should be cleaned daily to prevent the accumulation of dust. In addition, proper ventilation should be ensured to reduce the concentration of dust in the air.

A manufacturing company implemented the DC6060G dry vacuum graphite machining center and a comprehensive dust prevention and equipment maintenance program. After six months of operation, the company's production efficiency increased by 30%. The frequency of equipment breakdowns decreased by 50%, and the maintenance cost was reduced by 40%. This case clearly demonstrates the effectiveness of the DC6060G in improving production efficiency and reducing costs.

The DC6060G dry vacuum graphite machining center, with its advanced full - sealed enclosure design, high - efficiency dust collection device, and comprehensive maintenance guide, provides an excellent solution for graphite dust prevention and equipment maintenance in industrial processing. If you want to improve your production efficiency, reduce equipment failures, and achieve green production, don't miss this opportunity. Click here to learn more about the DC6060G and our dust prevention solutions.