Graphite materials are widely used in various industries due to their excellent properties. However, during the machining process, graphite dust can cause serious problems. Studies show that up to 80% of equipment failures in graphite machining are related to dust pollution. The dust generated in graphite processing can corrode machine parts and damage electronic components, leading to frequent breakdowns and reduced equipment lifespan.

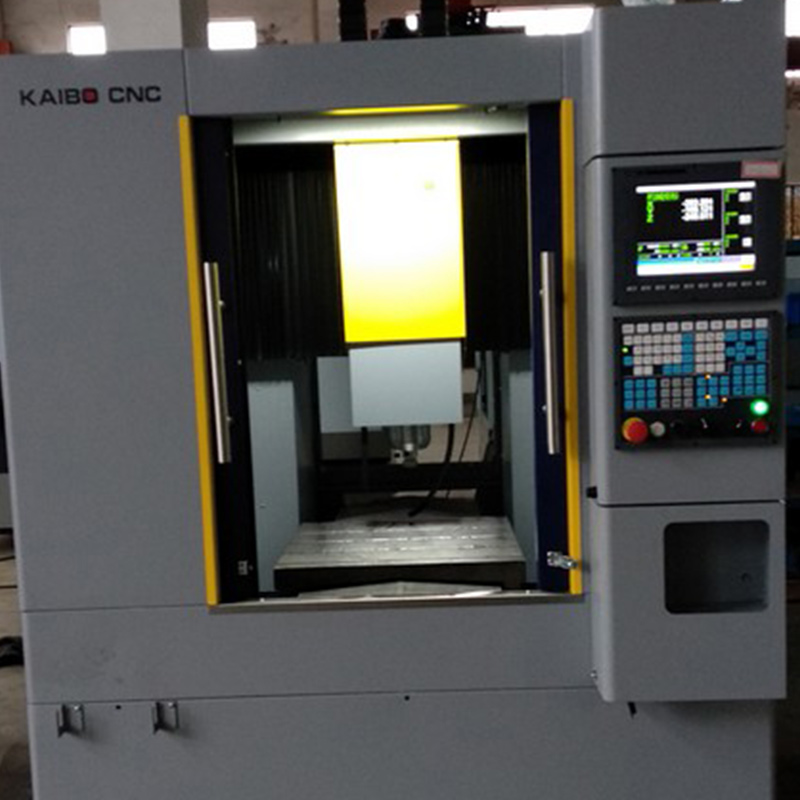

The DC6060G dry vacuum graphite machining center is a revolutionary solution in the industry. Its fully sealed enclosure structure, combined with a high - efficiency dust suction device, offers a unique approach to dust control. The fully sealed enclosure acts as a physical barrier, preventing graphite dust from escaping into the machine's internal components. The high - efficiency dust suction device can capture up to 95% of the generated dust, according to internal tests.

The design of the fully sealed enclosure is based on advanced engineering concepts. It uses high - quality sealing materials to ensure a tight fit, preventing even the smallest dust particles from entering. The dust suction device is designed with a powerful motor and a well - structured filtration system. The motor generates a strong suction force, while the filtration system effectively separates the dust from the air, ensuring clean air is released back into the environment.

Proper maintenance is crucial for the long - term performance of the DC6060G. Here are some practical maintenance tips:

Regularly inspect the seals of the fully sealed enclosure. A simple way is to use a smoke test. If there is any leakage, replace the seals immediately. It is recommended to conduct this check at least once a month.

Clean the filters of the dust suction device every two weeks. Over time, the filters can become clogged, reducing the suction efficiency. Also, check the motor's performance and lubricate the moving parts as needed.

Keep the working environment clean. Remove any accumulated dust around the machine. A clean environment can also prevent secondary dust pollution.

Several graphite machining companies have adopted the DC6060G solution. One company reported a 60% reduction in equipment downtime after using the DC6060G for six months. Another company saw a 30% increase in production efficiency due to fewer breakdowns and less time spent on equipment maintenance. These real - world examples demonstrate the effectiveness of the DC6060G in improving production safety and efficiency.

The field of graphite dust control and equipment maintenance is constantly evolving. We are committed to continuous research and development to improve the performance of our products. If you are looking for a reliable solution for graphite dust control and equipment maintenance, the DC6060G is your best choice. Click here to learn more and consult with our experts!