In 2024, the manufacturing industry's vacuum technology is undergoing a crucial upgrade. The fully - sealed design has emerged as a core breakthrough for enhancing graphite processing precision and equipment lifespan. This article delves into how the dry vacuum graphite machining center DC6060G can effectively block dust corrosion, extend mechanical life through its sealed cover structure and high - efficiency dust collection system, and achieve real - time monitoring and automatic diagnosis with intelligent control, helping enterprises enter a new stage of intelligent manufacturing featuring high precision and low maintenance.

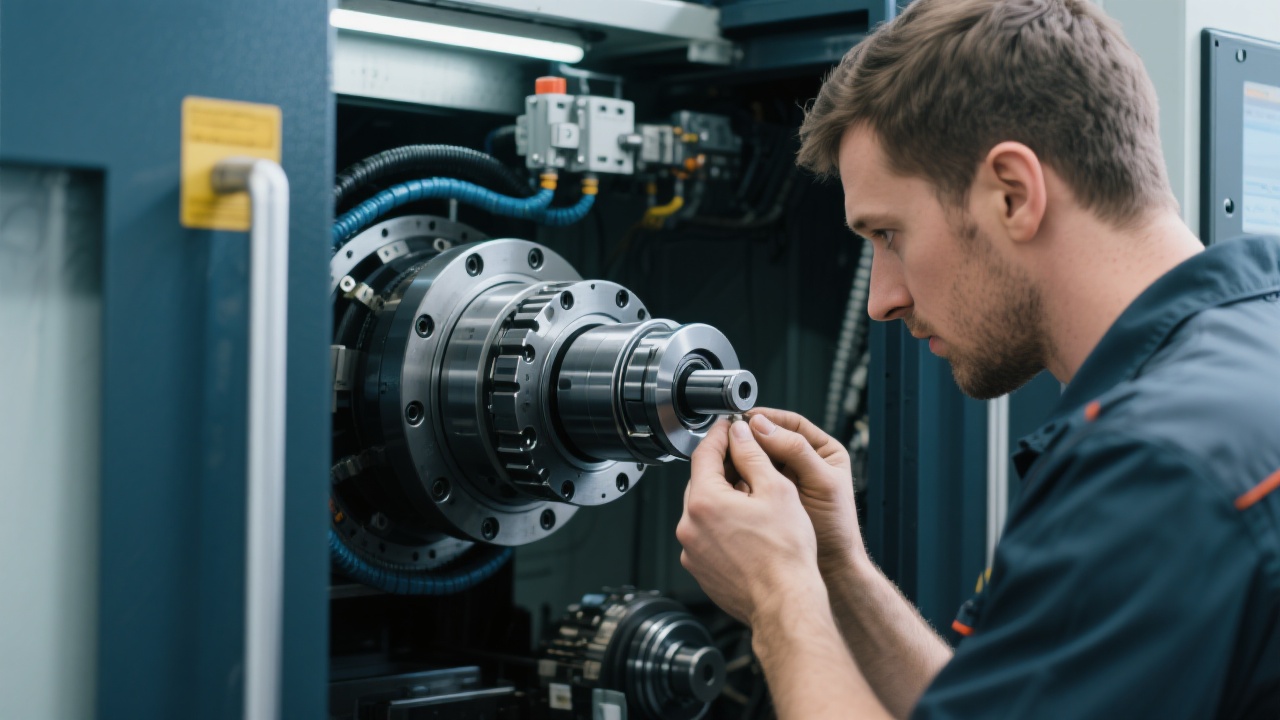

In graphite processing, dust is a major enemy. It can cause corrosion to machine components, leading to reduced processing accuracy and shortened equipment life. According to industry data, in traditional non - sealed graphite processing environments, the average lifespan of machine tools is reduced by about 30% due to dust corrosion. However, the fully - sealed design of modern vacuum equipment can effectively address this issue. As shown in the following illustration (Figure 1), the comparison between a non - sealed structure and a fully - sealed structure clearly reveals that the fully - sealed structure can isolate dust from the internal components of the equipment.

A well - sealed structure can maintain a stable internal environment for the equipment, which is essential for high - precision processing. For example, in the DC6060G, the sealed cover effectively prevents dust from entering the key components of the machine, ensuring that the processing accuracy can be maintained at a high level for a long time. It has been reported that in some enterprises using DC6060G, the processing accuracy has been improved by about 20% compared with traditional equipment.

In addition to the sealed structure, the dust collection device also plays a vital role in graphite processing. A high - efficiency dust collection system can quickly remove the dust generated during processing, further reducing the impact of dust on the equipment. In the DC6060G, the dust collection system has a high - power suction capacity, which can collect more than 95% of the dust generated during processing.

This not only improves the working environment but also significantly reduces the wear and tear of the equipment. According to user feedback, after using the DC6060G with an efficient dust collection system, the frequency of equipment maintenance has been reduced by about 40%, and the downtime has been shortened by about 30%, greatly improving production efficiency.

The DC6060G has many application advantages in graphite processing scenarios. Firstly, it can significantly reduce downtime. Thanks to its sealed structure and efficient dust collection system, the equipment is less likely to break down due to dust problems, ensuring continuous production. Secondly, it can improve tool life. In a dust - free environment, the wear of cutting tools is greatly reduced. Some users have reported that the service life of cutting tools in the DC6060G has been extended by about 50% compared with traditional processing equipment.

The development of vacuum technology in the manufacturing industry is also closely integrated with intelligent manufacturing trends. Digital control and remote monitoring technologies have brought new impetus to equipment operation and maintenance efficiency. In the DC6060G, intelligent control systems can achieve real - time monitoring of equipment status. For example, sensors can collect data on temperature, vibration, and other parameters of the equipment, and transmit them to the control center. Once an abnormal situation is detected, the system can issue an alarm in time and even perform automatic diagnosis and adjustment.

Remote monitoring technology allows technicians to monitor and control the equipment from anywhere, which is especially useful for multinational enterprises or those with multiple production sites. According to industry experts' views (as shown in the following quote box), "The integration of intelligent manufacturing and vacuum technology is an inevitable trend in the future, which will bring higher efficiency and lower costs to the manufacturing industry."

"The integration of intelligent manufacturing and vacuum technology is an inevitable trend in the future, which will bring higher efficiency and lower costs to the manufacturing industry." - Industry Expert

Looking ahead, the development of vacuum technology in the manufacturing industry will continue to move towards higher precision, greater intelligence, and better environmental adaptability. The integration of new materials and new processes will further improve the performance of vacuum equipment. For enterprises, it is necessary to actively consider how to optimize their production processes according to these trends.

Are you interested in learning more about how to optimize your graphite processing line with the latest vacuum technology? Do you have any questions about the application of DC6060G in your production environment? Click here to enter our Q&A section and share your thoughts and questions with us.