In the graphite processing industry, graphite dust generated during the machining process poses a significant threat to the normal operation of machine tools. Understanding the physical properties of graphite dust and its corrosion mechanism is the first step in addressing this issue.

Graphite dust is characterized by its fine particles, high hardness, and chemical stability. When it adheres to machine tool parts and electronic components, it can cause abrasion and corrosion. For example, in some graphite processing plants, the corrosion rate of machine tool parts exposed to graphite dust has increased by about 30% compared to those in a dust - free environment. The dust can penetrate into the gaps of mechanical parts, causing increased friction and wear, and even leading to mechanical failures. In electronic components, it can cause short - circuits and malfunctions, reducing the reliability and service life of the equipment.

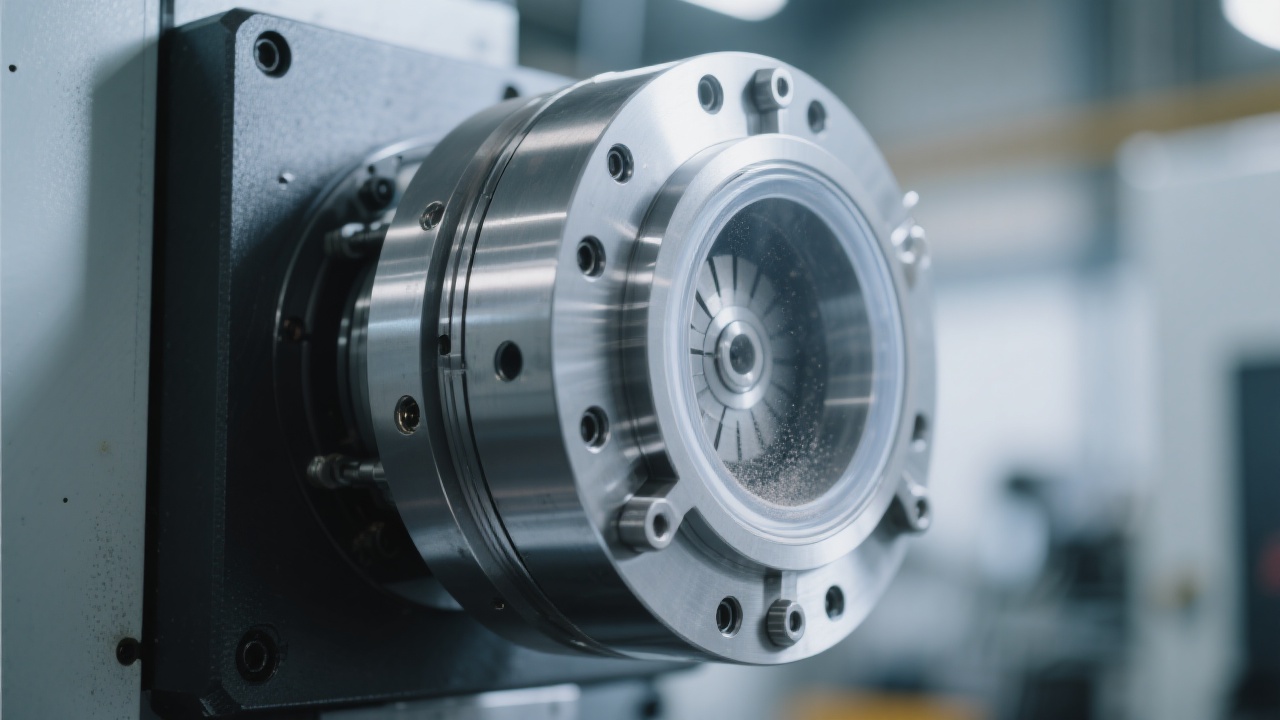

The Dry Vacuum Graphite Machining Center DC6060G is a revolutionary solution in the graphite processing industry. Its fully enclosed cover design is one of its key features. The fully enclosed cover is made of high - strength and corrosion - resistant materials, which can effectively prevent graphite dust from escaping into the surrounding environment. The sealing performance of the cover can reach an air leakage rate of less than 1%, ensuring that almost all the dust generated during the machining process is confined within the machining area.

In addition to the fully enclosed cover, the DC6060G is also equipped with a high - efficiency dust suction device. The dust suction device works on the principle of negative pressure. It can quickly suck the graphite dust generated during the machining process into the dust collection box. The dust collection efficiency can reach up to 95%, greatly reducing the concentration of dust in the machining area. This not only protects the machine tool from dust corrosion but also improves the working environment for operators.

Regular maintenance of the Dry Vacuum Graphite Machining Center DC6060G is crucial to ensure its long - term stable operation. Here are some key maintenance points:

By implementing these scientific dust prevention and maintenance measures, enterprises can significantly improve the production safety, machining accuracy, and service life of equipment. For example, a graphite processing enterprise in Europe adopted the DC6060G and corresponding maintenance measures, and the equipment failure rate was reduced by 40% within one year, and the machining accuracy was improved by about 20%.

In conclusion, the Dry Vacuum Graphite Machining Center DC6060G, with its unique fully enclosed cover design and high - efficiency dust suction device, provides an excellent solution for graphite dust control in the machine tool industry. If you want to learn more about how to protect your machine tools from graphite dust corrosion and improve production efficiency, click here to get more professional advice and solutions.