In the precision manufacturing sector of 2024, the evolution of vacuum technology is revolutionizing graphite machining processes. The DC6060G dry vacuum processing center emerges as a breakthrough by integrating a fully sealed enclosure with an optimized dust extraction system. This synergy not only curtails particulate contamination but significantly extends equipment lifespan—by over 30%—translating into cleaner production lines and smarter, more sustainable manufacturing.

The manufacturing industry is witnessing accelerated adoption of vacuum-based machining centers, driven by demands for higher precision, reduced contamination, and enhanced operational longevity. Industry reports forecast a 15% annual increase in vacuum equipment deployment in graphite machining sectors globally, fueled by the critical need to mitigate the abrasive, corrosive nature of graphite dust which threatens conventional machining accuracy and maintenance costs.

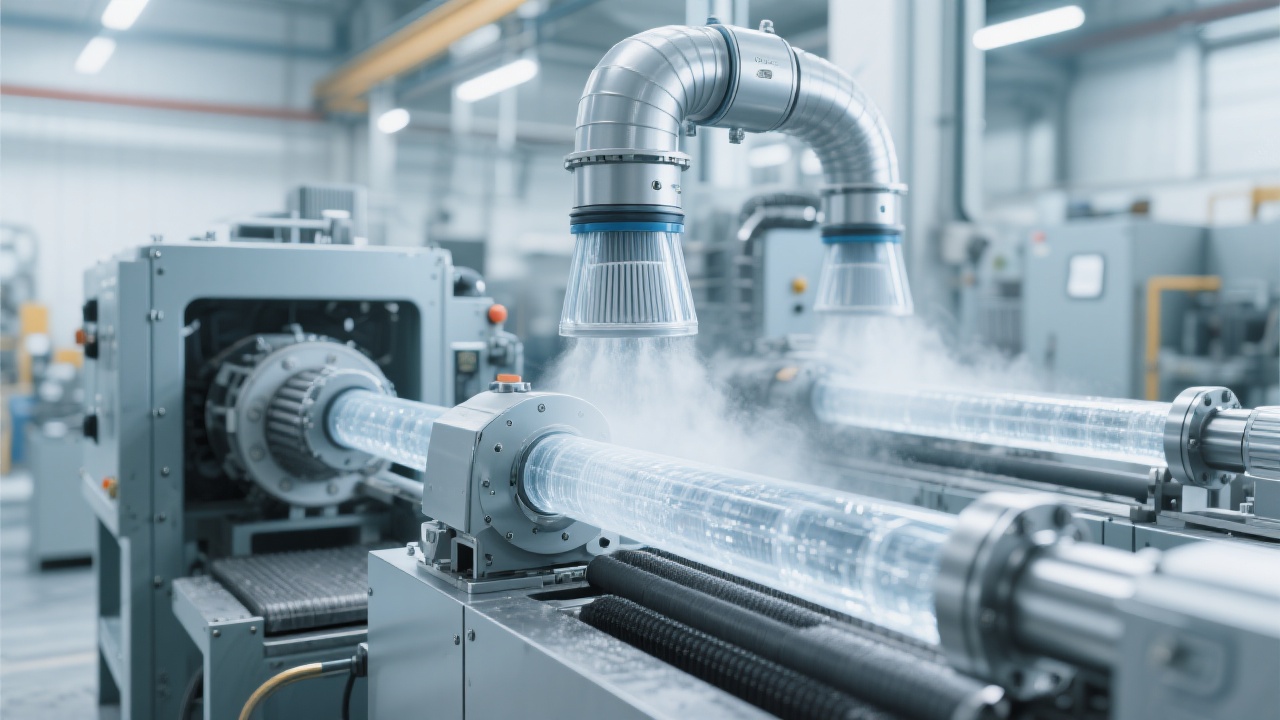

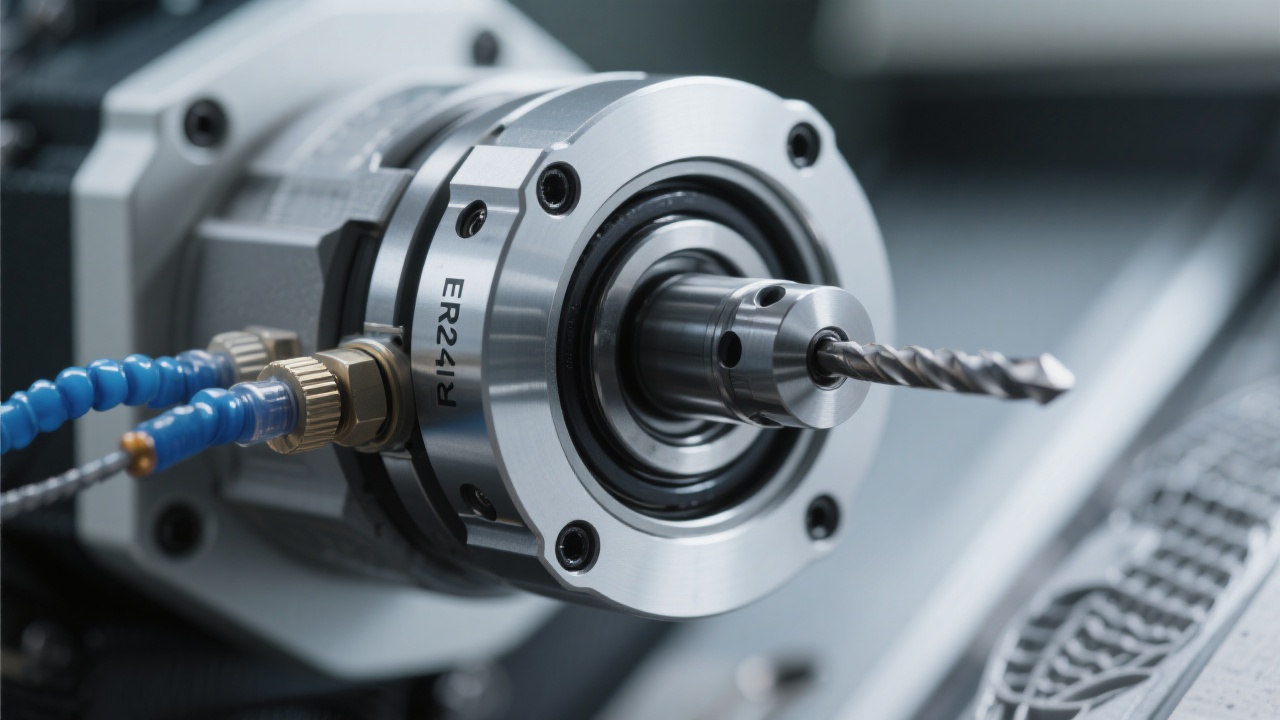

The DC6060G features a meticulously engineered fully sealed enclosure designed to isolate the work chamber from external contamination and contain graphite dust within the system. Utilizing multiple layers of airtight seals and pressure gradient control, this enclosure effectively prevents dust infiltration, thereby protecting sensitive electronics and internal mechanics from corrosion-induced wear.

| Feature | Description | Benefit |

|---|---|---|

| Multi-layer Seal Gaskets | Prevents dust penetration under pressure fluctuations | Reduces mechanical wear and contamination risk |

| Pressure Gradient Regulation | Maintains negative pressure in enclosure relative to surroundings | Ensures graphite dust containment even during door opening |

| Reinforced Structural Frame | Supports sealed enclosure integrity under operational stresses | Prolongs equipment service life by minimizing seal damage |

The DC6060G integrates a state-of-the-art dust extraction system with optimized airflow dynamics and HEPA-level filtration to capture over 99.7% of graphite particulates during machining. Real-world testing reveals a 50% reduction in contamination levels inside the control cabinet compared to legacy systems, which directly correlates with a lower failure rate of electronic components by 35%.

“The exceptional dust control of the DC6060G enabled uninterrupted 24/7 operation at our plant with significantly reduced downtime for electronic maintenance,” says John Miller, Senior Process Engineer at Precision Graphix Inc.

When benchmarked against traditional CNC milling centers, DC6060G demonstrates a measurable superiority:

| Parameter | Conventional Machine | DC6060G Vacuum Machine |

|---|---|---|

| Average Machining Accuracy | ±15 µm | ±7 µm |

| Mean Time Between Failures (MTBF) | 1,200 hours | 1,600 hours |

| Maintenance Downtime per Year | 160 hours | 95 hours |

The DC6060G is equipped with integrated PLC-based digital control systems and predictive maintenance algorithms that autonomously detect anomalies such as pressure drops, seal breaches, and filter saturation. This real-time monitoring reduces unplanned downtime by up to 40% and enables precise scheduling of servicing, aligning perfectly with Industry 4.0 standards.

“Independent tests by the National Manufacturing Institute confirmed that the DC6060G’s fully sealed design cuts graphite dust infiltration by 80%, directly improving parts yield by 12%,” states a recent industry whitepaper.

Customer testimonies further validate these findings, underscoring improvements in operational cleanliness, safety, and long-term cost savings.

Ready to elevate your graphite machining process with cutting-edge vacuum technology? Discover how DC6060G can make your production line cleaner, smarter, and more sustainable today.