In the highly competitive shoe mold manufacturing industry, the five-axis CNC milling machine DC6060A has emerged as a game - changer. This article delves deep into the core technical advantages of this machine, offering practical tips on maintenance and troubleshooting to help shoe mold manufacturers enhance efficiency and competitiveness.

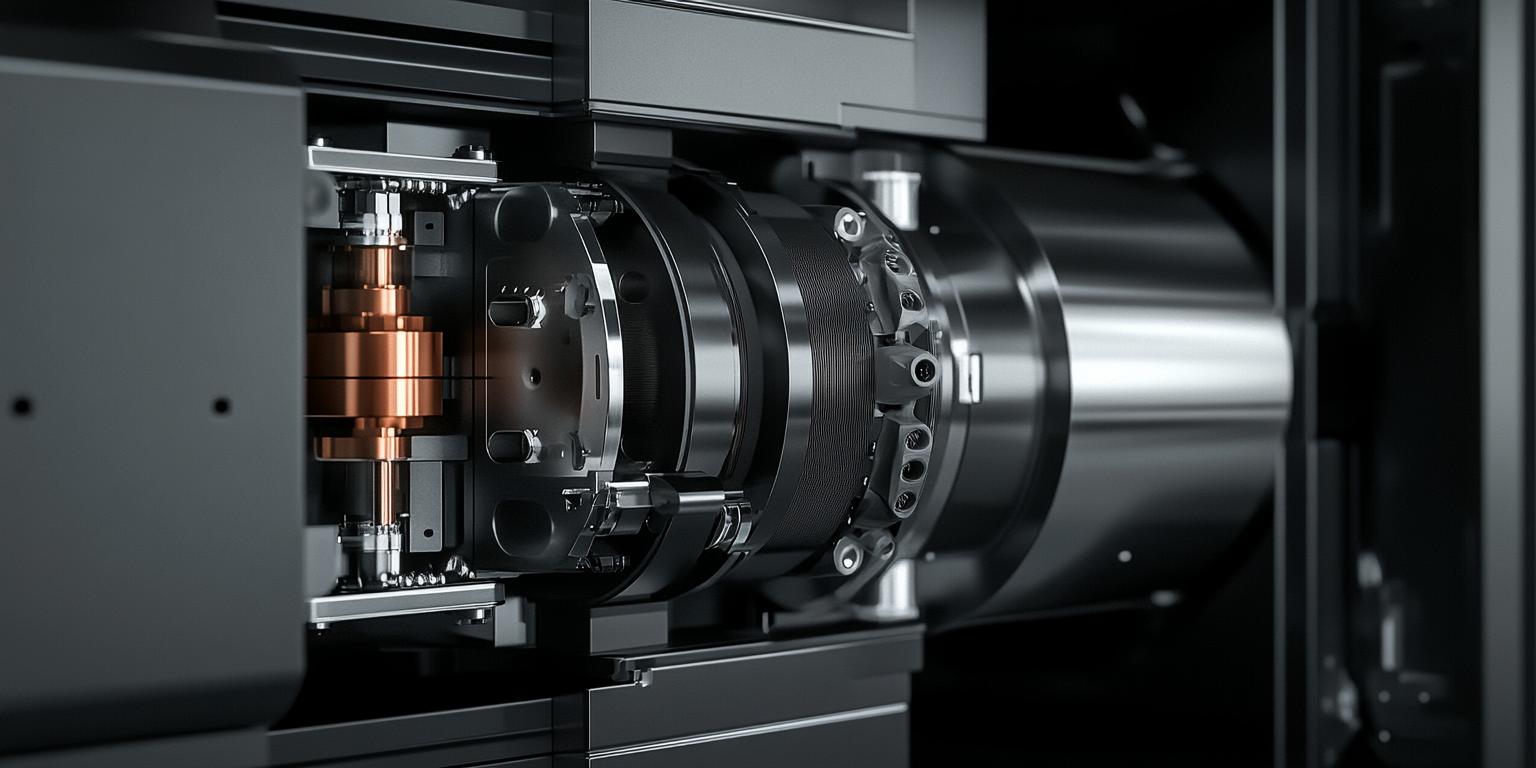

The DC6060A is equipped with advanced multi - axis linkage technology. Unlike traditional milling machines, it can simultaneously control multiple axes, enabling complex movements during the machining process. With this technology, the machine can achieve an angular positioning accuracy of up to ±0.005°, which significantly improves the precision of shoe mold manufacturing. According to industry reports, multi - axis linkage technology can increase the machining efficiency by up to 40% compared to three - axis machines.

Another remarkable feature is its multi - angle cutting ability. It can cut from various angles, allowing for the creation of complex shoe mold shapes. This is particularly useful for manufacturing high - end shoe molds with unique designs. The machine's ability to perform multi - angle cutting reduces the need for re - clamping, which not only saves time but also minimizes errors caused by re - positioning.

When it comes to complex shoe mold surface machining, the DC6060A shines. It can handle complex curved surfaces with ease, thanks to its high - speed spindle and advanced control system. The spindle speed can reach up to 12,000 RPM, ensuring smooth and efficient machining of complex shoe mold surfaces. This is crucial for producing high - quality shoe molds that meet the ever - increasing demands of the market.

To fully utilize the capabilities of the DC6060A, it is essential to understand its operation process and debugging points. The operation process starts with loading the CAD/CAM design file into the machine's control system. The operator then needs to set up the machining parameters, such as cutting speed, feed rate, and depth of cut, according to the material and complexity of the shoe mold.

Debugging is a critical step to ensure the accuracy and stability of the machine. During debugging, the operator should check the alignment of the axes, the calibration of the sensors, and the performance of the cutting tools. Regular debugging can prevent potential problems and improve the overall performance of the machine.

Proper maintenance is the key to extending the service life of the DC6060A and ensuring its stable operation. Regular cleaning of the machine is necessary to remove dust and debris, which can affect the performance of the machine. The lubrication system should also be checked regularly to ensure that all moving parts are well - lubricated. According to statistics, regular maintenance can reduce the failure rate of the machine by up to 30%.

When it comes to troubleshooting, common problems such as axis movement errors, spindle overheating, and tool breakage can be resolved with the right approach. For example, if the axis movement error occurs, the operator should first check the encoder and the drive system. If the spindle overheats, it may be due to insufficient lubrication or a malfunctioning cooling system.

By optimizing the operation and maintenance of the DC6060A, shoe mold manufacturers can significantly reduce costs. The improved efficiency means less time spent on each shoe mold, which translates into lower labor costs. Moreover, the high - precision machining reduces the scrap rate, saving on material costs.

With the ability to produce high - quality shoe molds more efficiently, manufacturers can enhance their market competitiveness. They can meet the demands of customers more quickly and offer better - quality products, which can lead to increased customer satisfaction and loyalty.

Are you ready to take your shoe mold manufacturing to the next level? Discover how the five - axis CNC milling machine DC6060A can transform your production process and boost your competitiveness. Click here to learn more